Rhenium-Tungsten Parts

If you have any inquiries, please contact us.

- Tokyo+81-3-3457-4874

Open 9:00am-5:00pm (business days)

Contact UsRhenium-tungsten (Rheni-tung) Targets (Rotating Anodes)

Tungsten has a high melting point and generates X-rays when irradiated with a high-speed electron beam. Because of these properties, it is used as an X-ray source for various X-ray tubes used in medical and security devices.

Toshiba Materials produces targets with Rheni-tung, an alloy that is extremely strong and tough (resistant to cracking and swelling). These include standard Rheni-tung targets in which Rheni-tung is combined with a molybdenum alloy, and Rheni-tung/graphite targets in which some of the molybdenum alloy is replaced with graphite for a lighter weight. These targets are used for medical X-ray tubes.

Features

- Strong and compatible with high-output electron beams

- High precision; shafts will not lose precision at high rotations

- High strength, toughness and heat resistance

Product specifications

We draw on our wealth of knowledge to meet a wide range of requests.

Target of other materials

Examples of uses

- Medical X-ray tubes (standard X-ray tubes, X-ray tubes for CT scanners, X-ray tubes for circulation devices)

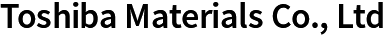

Probe Pins

Tungsten is a strong, wear-resistant metal that is used make probe pins (contact pins) for inspecting high-density integrated circuits in parts such as semiconductors and liquid crystal panels. Toshiba Materials has developed Rheni-tung, an alloy in which rhenium is added to tungsten to further improve its properties. It has high strength and high conductivity, and at the same time, it has a smooth pin tip due to trace element control technology, making it suitable for probe pins.

Features

- Outstanding electrical conductivity, strength and wear resistance

- Extremely smooth pinpoint surface

Product specifications

Product name and materials

| Products name | Types of materials |

|---|---|

| H30 | 3% rhenium-tungsten |

| H37 | 3% rhenium-tungsten |

| H36 | 26% rhenium-tungsten |

| W31 | Pure tungsten |

Standard size, surface treatment

- Standard size, surface treatment

- Diameter: dia 0.005 - dai 0.5 x L (mm)

- Surface treatment

- Electrolytic polishing

- Gold or nickel plating (full or partial)

Examples of uses

- Inspection of high-density integrated circuits in parts such as semiconductors and liquid crystal panels

Rhenium-Tungsten (Rheni-tung) Wires

Rhenium and tungsten have different electrical resistance and mechanical properties, and the electrical resistance and mechanical properties of the Rheni-tung alloy change depending on the amount of rhenium added to tungsten. Toshiba Materials has a lineup of wires that can be applied to various applications by taking advantage of the characteristics of tungsten.

Features

- Homogeneous and highly functional with few cracks

- Wide range of wires with a variety of properties

Product specifications

Material

| Re (wt%) |

K (ppm) |

Fe (ppm) |

Mo (ppm) |

W* (wt%) |

Features | |

|---|---|---|---|---|---|---|

| H30 | 3 | ≤ 100 | ≤ 30 | ≤ 50 | ≥ 99.95 | Outstanding non-sag properties due to addition of doping material |

| H36 | 26 | ≤ 5 | ≤ 30 | ≤ 50 | ≥ 99.95 | High quantity of rhenium has been added for high electrical resistance and mechanical strength |

| H37 | 3 | ≤ 5 | ≤ 30 | ≤ 50 | ≥ 99.95 | Ideal for probe pins for purposes such as semiconductor inspections |

| H38 | 5 | ≤ 100 | ≤ 30 | ≤ 50 | ≥ 99.95 | Used on the + (positive) side of thermocouples |

| H39 | 26 | ≤ 5 | ≤ 30 | ≤ 50 | ≥ 99.95 | Used on the - (negative) side of thermocouples |

*: Purity of tungsten excluding rhenium

- Sizes: Inquire for details

Examples of uses

- Probe pins

- Various inspection tools

- Display tubes

- Electron tube heaters

- Thermocouples