Silicon Nitride Ceramics for Machine Parts

If you have any inquiries, please contact us.

- Tokyo+81-3-3457-4874

Open 9:00am-5:00pm (business days)

Contact UsSilicon Nitride Ceramics for Machine Parts

Toshiba Materials' silicon nitride is lightweight and has excellent wear resistance and corrosion resistance properties. From these characteristics, it is used in automotive and industrial machine parts applications. Toshiba Materials manufactures and sells Silicon Nitride Ceramics parts such as ball blanks(for bearings).

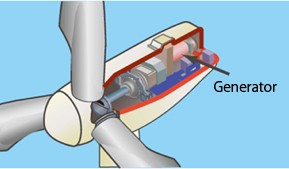

In bearing applications, silicon nitride is contributing to weight reduction and performance improvement of various applications, and leading to replacement of steel balls. Our material is widely used as standard material in the market and also designated as certified material for aircraft engine application by various companies. It was also used in the bearing of turbo pumps of the Space Shuttle, which was launched from 1995.

In addition, it has a proven track record in check valves for supply pumps for diesel engines (common rail system) that require wear resistance and high rigidity, check balls for fuel injection ports, bearing balls for aircraft engines, etc. It is also used in bearing balls of motors for electric vehicles that require electrical corrosion resistance characteristic and used in a wide range of fields.

Features

- Low density (less than half the weight of a steel ball of the same size)

- High heat resistance

- Resistant to electrical corrosion as it is an insulator

- Resistant to corrosion and rust caused by acids and alkalis

- Not easily affected in a strong magnetic field as it is a non-magnetic material

Product specifications(List of representative values)

| Items | Measuring method |

Measuring temperature |

Unit | Silicon nitride(Si3N4) | ||

|---|---|---|---|---|---|---|

| TSN-03NH | TSN-23HA | NEW! TSN-33H |

||||

| Density | JIS Z8807 | RT | g/cm3 | 3.24 | 3.27 | 3.25 |

| Hardness (HV(196N)) | JIS R1610 | RT | - | 1,500 | 1,500 | 1,500 |

| Three point bending strength |

JIS R1601 ASTM C1239 |

RT | MPa | 1,000 | 900 | 850 |

| Compression strength | JIS R1608 | RT | MPa | 5,500 | 5,000 | Under measurement |

| Young's modulus | JIS R1602 | RT | GPa | 303 | 315 | 317 |

| Poisson's ratio | JIS R1602 | RT | - | 0.28 | 0.28 | 0.28 |

| Fracture toughness | ASTM F2094 | RT | MPa・m1/2 | 6~8 | 5~7 | 5~7 |

| Coefficient of thermal expansion |

JIS R1618 | RT~500℃ | x10-6/K | 2.7 | 2.7 | 2.8 |

| Volume resistivity | JIS C2141 | RT | Ω・m | >1012 | >1012 | >1012 |

| Corrosion resistance※ | Acid | RT | - | Good | Good | Under measurement |

| Alkali | RT | - | Good | Good | Under measurement | |

| ASTM F2094 (Material Class) | Ⅰ | Ⅱ | Ⅱ | |||

| Features | High strength Ideal for applications requiring high characteristic reliability, such as machine tools, industrial equipment, medical equipment, and aircraft. |

Adopted for wind power generation.Can be used for large spheres. | Low cost Ideal for applications requiring low cost and large quantities, such as electric vehicles. |

|||

| Main recommended applications | Bearings,Engine parts,Mechanical parts | Bearings,Engine parts,Wind power generation | Bearings | |||

※Corrosion resistances were measured under following conditions.

Acid;96hours immersion at RT in 36%HCl,95%H2SO4 and 60%HNO3. Alkali;in 5%NaOH,40%NaOH.

※The values in the table are reference values,not guaranteed values.

Application example of finished product after polishing

- Bearings for wind power generators

- Machine tools

- Aircraft engines

- Medical drills and other medical equipment

- Motors for electric vehicles, hybrid vehicles, etc.

- Turbo pump

- Fan motor

- Check ball for fuel injection system for diesel engine

- Check valve for supply pump for diesel engine